APEX Preform Mold Manufacturing Factory: Delivering Precision and Efficiency in PET Production

APEX Preform Mold Manufacturing Factory: Delivering Precision and Efficiency in PET Production

In the fast-paced world of plastic packaging, PET preform molds are the backbone of producing high-quality bottles for beverages, pharmaceuticals, cosmetics, and more. APEX Preform Mold Manufacturing Factory stands at the forefront of this industry, offering precision-engineered preform molds that combine innovation, durability, and cost-effectiveness. This article explores the key advantages of partnering with APEX for preform mold manufacturing, along with the SEO keywords to amplify your search visibility.

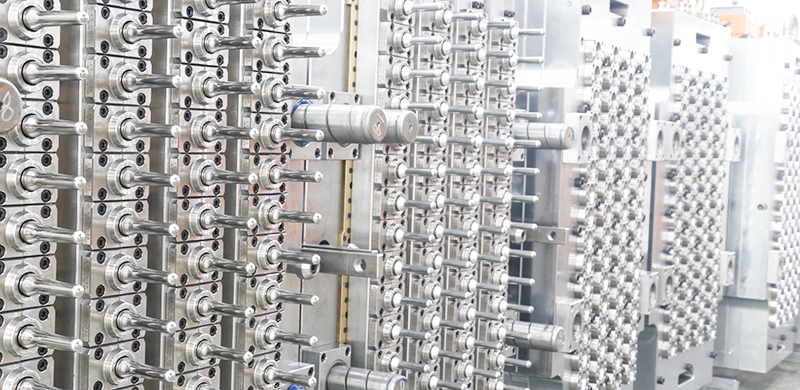

1. Precision Engineering for Superior Preform Quality

APEX utilizes state-of-the-art CAD/CAM design software, CNC machining, and EDM technologies to craft molds with micron-level accuracy. Our PET preform molds are optimized to produce uniform wall thickness, consistent neck finishes, and flawless thread geometry—critical for ensuring airtight seals and compatibility with blow-molding machines.

Key benefits:

Perfect alignment for high-speed injection molding.

Reduced material waste and cycle times.

Custom designs for unique bottle shapes (e.g., carbonated drink bottles, pharmaceutical containers).

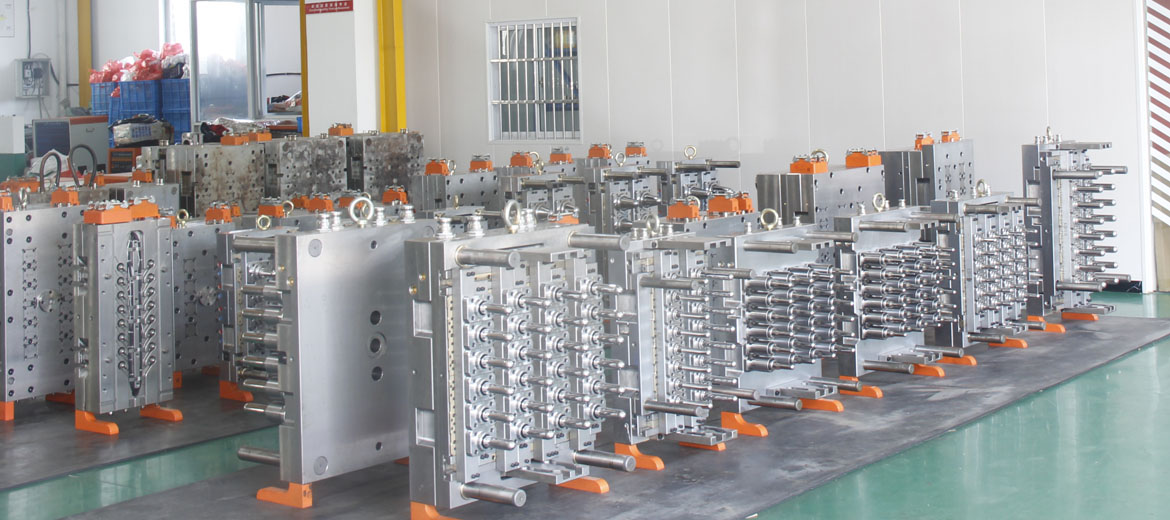

2. High-Quality Materials for Longevity

APEX molds are built to last. We use premium materials like hardened steel (H13, S136) and billets to withstand high-pressure injection cycles and abrasive PET resins. This ensures:

Extended mold lifespan (1 million+ cycles).

Minimal downtime for maintenance.

Resistance to corrosion and wear.

3. High-Volume Production Efficiency

For industries requiring mass production, APEX designs multi-cavity preform molds (e.g., 48-, 72-, or 144-cavity configurations) paired with hot runner systems. This setup maximizes output by producing dozens of preforms per cycle while maintaining energy efficiency and reducing resin waste.

Ideal for:

Beverage companies producing millions of bottles annually.

Cosmetic brands needing lightweight, durable packaging.

4. Advanced Quality Control

APEX adheres to stringent quality assurance protocols, including:

CMM (Coordinate Measuring Machine) inspections for dimensional accuracy.

Mold flow analysis to optimize resin distribution.

Pressure and temperature testing to ensure consistent performance.

This guarantees that every PET preform mold meets global standards like FDA, ISO, and EU regulations for food safety and sustainability.

5. Customization for Diverse Applications

No two industries have the same needs. APEX collaborates closely with clients to develop custom preform molds tailored to specific requirements:

Lightweight preforms for eco-friendly bottles.

Barrier-layer molds to extend product shelf life.

Specialized neck designs for child-resistant or tamper-evident closures.

6. Fast Turnaround and After-Sales Support

APEX’s streamlined manufacturing process and experienced engineering team ensure quick mold delivery without compromising quality. We also provide:

Comprehensive technical support during mold trials.

Maintenance training and spare parts services.

Rapid troubleshooting to minimize production disruptions.

7. Sustainability-Driven Solutions

As industries shift toward circular economies, APEX integrates sustainable practices into mold design:

Energy-efficient hot runner systems.

Molds optimized for recycled PET (rPET) resins.

Designs that reduce material usage without compromising strength.

Industries Served by APEX Preform Molds

Beverage: Water, soda, juice, and alcohol bottles.

Pharmaceutical: Medical-grade containers with precise dosing.

Cosmetics & Personal Care: Premium packaging for creams, lotions, and serums.

Household Chemicals: Detergent and cleaning product bottles.

Why Choose APEX Preform Mold Manufacturing Factory?

Decades of Expertise: Proven track record in PET preform mold design.

Cutting-Edge Technology: Advanced machinery for precision and speed.

Global Compliance: Molds meet FDA, ISO, and regional safety standards.

Cost Savings: High-efficiency molds reduce per-unit production costs.

End-to-End Support: From design to after-sales service.

Conclusion

For businesses seeking high-performance PET preform molds, APEX Preform Mold Manufacturing Factory delivers unmatched precision, durability, and innovation. Our commitment to quality and sustainability ensures your packaging solutions meet the demands of today’s competitive markets.

Contact APEX today to discuss your custom preform mold requirements and elevate your production capabilities!