Precision Wide-Mouth PET Preform Molds Engineered for Performance & Efficiency

Precision Wide-Mouth PET Preform Molds Engineered for Performance & Efficiency

In the competitive world of PET packaging, wide-mouth jars reign supreme for products requiring easy filling, scooping, or pouring – think nut butters, sauces, dairy, coffee, cosmetics, and household chemicals. At the heart of producing flawless, high-performance preforms for these jars lies the specialized wide-mouth PET preform mold. Manufacturing these complex tools demands unique expertise, distinguishing a dedicated factory from general mold makers.

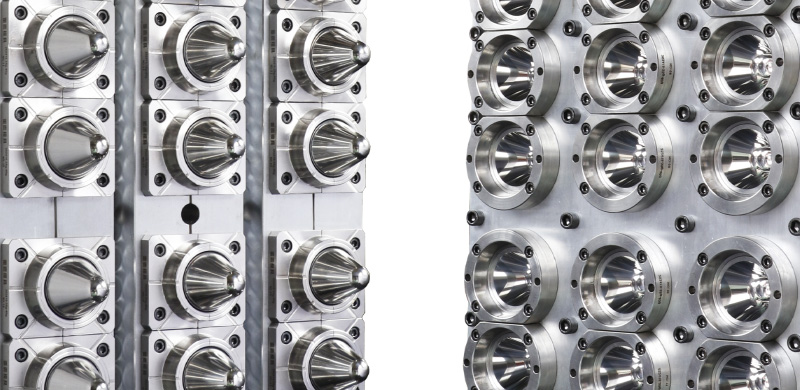

Dedicated Multi-Cavity Designs:

Expertise in high-cavitation molds (32, 48, 72+ cavities) specifically engineered for the larger geometry and material distribution challenges of wide-mouth preforms.Reinforced Core & Cavity Structures:

Utilizes high-strength tool steels (e.g., H13, S136, Stavax ESR) with specialized heat treatment to withstand the significant injection pressures and mechanical stresses inherent in forming large-diameter necks.Advanced Cooling Channel Engineering:

Implements conformal cooling (3D printed channels) or optimized baffle/bubbler systems around the thick neck and shoulder sections to achieve uniform cooling, minimize cycle time, and prevent sink marks/warpage.Precision-Guided Split Cores (Hoffman Blocks):

Incorporates ultra-precise, wear-resistant split core mechanisms for flawless formation of the critical wide-mouth thread profile and sealing surfaces, ensuring consistent closure performance.Optimized Hot Runner Systems:

Integrates high-performance, balanced hot runner manifolds (e.g., Husky, Yudo, Mold-Masters) with valve-gate technology tailored for even filling of large preform diameters and clean gate vestige removal.Enhanced Venting Solutions:

Features intricate micro-venting channels and porous inserts specifically placed in the neck finish and body transition zones to eliminate air traps and burn marks common in bulky sections.Rigorous Dimensional Control:

Employs precision machining (CNC, EDM), grinding, and metrology (CMM) to guarantee critical tolerances on thread dimensions, inner neck diameter (ID), and ovality for perfect cap sealing compatibility.Robust Ejection Systems:

Designs reinforced stripper plates or dual-stage ejection mechanisms to ensure reliable, distortion-free demolding of the large-diameter preform without damage.Specialized Surface Finishes:

Applies tailored surface texturing (e.g., VDI, SPI) or high-polish finishes (e.g., SPI A1) inside the neck and sealing areas to meet specific customer requirements for barrier properties, clarity, or de-molding.Validated Mold Flow Analysis (MFA):

Utilizes advanced simulation (Moldflow, Moldex3D) pre-manufacturing to predict and optimize filling patterns, cooling efficiency, shrinkage, and stress distribution for wide-mouth geometry.

Distinctive Factory Capabilities:

Material Expertise: Deep understanding of processing PET, rPET, and specialty barrier resins for wide-mouth applications (sauces, dairy, nutraceuticals).

Rapid Prototyping: Ability to produce functional prototype molds for customer trials and design validation.

High-Performance Testing: In-house testing of cycle times, cooling efficiency, and preform quality metrics (weight, dimensions, crystallinity).

Comprehensive Support: Offers design-for-manufacturability (DFM) consultation, mold maintenance programs, and technical process optimization.

These features collectively ensure the production of high-precision, durable, and efficient molds specifically designed for the demanding requirements of wide-mouth preform manufacturing, setting a specialized factory apart from general mold makers.

Our Factory's Hallmarks of Excellence in Wide-Mouth Mold Manufacturing:

Advanced Conformal Cooling: We leverage cutting-edge 3D printing (DMLS/SLM) to create optimally contoured cooling channels within the core and cavity. This dramatically improves cooling uniformity around the thick neck and shoulder, reducing cycle times by up to 25%, eliminating warpage, and ensuring preform crystallinity consistency critical for performance.

Reinforced Structural Integrity: Utilizing premium tool steels (H13, S136, Stavax ESR) subjected to rigorous heat treatment, our molds feature robust core and cavity designs specifically calculated to endure the intense pressures of wide-mouth preform injection molding, guaranteeing exceptional mold longevity and durability.

Precision Split-Core Technology: Our molds incorporate high-precision, wear-resistant split cores (Hoffman blocks) guided by hardened steel components. This guarantees micrometer-accurate formation of critical wide-mouth threads, tamper-evident bands (TEBs), and sealing surfaces, ensuring perfect cap application and leak-proof seals every time.

Optimized Valve-Gate Hot Runners: We integrate top-tier hot runner systems (Husky, Yudo, Mold-Masters) meticulously balanced for wide-mouth geometries. Valve-gate technology ensures clean gate cuts, minimal vestige, and precise control over material flow into the large preform opening, preventing jetting and flow lines.

Intelligent Venting Solutions: Strategically placed micro-vents and porous metal inserts effectively evacuate trapped air from deep cores and complex neck features, eliminating burn marks and voids to achieve pristine preform surfaces, especially crucial for transparent applications.

Rigorous Simulation & Validation: Every design undergoes comprehensive Mold Flow Analysis (MFA) using industry-standard software (Moldflow, Moldex3D) before metal is cut. We simulate filling patterns, cooling efficiency, shrinkage, and stress distribution specifically for wide-mouth dynamics to preemptively solve potential issues.

Application-Specific Expertise: We possess deep knowledge in processing standard PET, recycled PET (rPET), and specialty barrier resins tailored for the demanding requirements of food, beverage, personal care, and chemical packaging using wide-mouth formats.

End-to-End Quality Assurance: From precision machining (CNC, Wire EDM, Sink EDM) and grinding to final metrology (CMM inspection), we enforce stringent dimensional control on all critical features (threads, ID, ovality). Our commitment is backed by ISO 9001:2015 certification.