Plastic Medicine Bottle Cap Mold Manufacturers: A Comprehensive Guide

Plastic Medicine Bottle Cap Mold Manufacturers: A Comprehensive Guide

Introduction

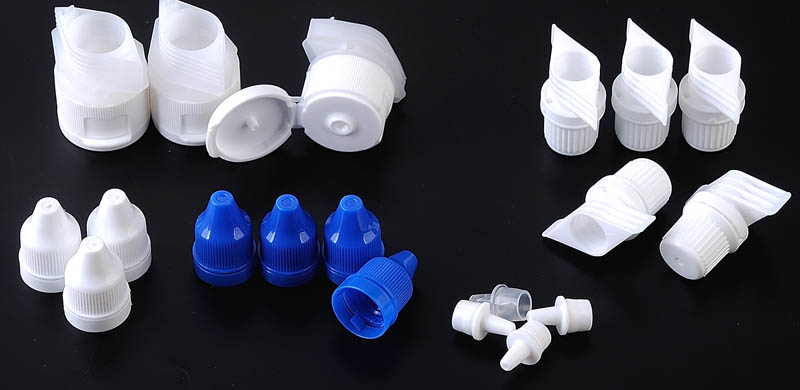

Plastic medicine bottle cap molds are essential in the pharmaceutical packaging industry, ensuring safety, durability, and precision. As a leading plastic medicine bottle cap mold manufacturer, we specialize in high-quality injection molds for pharmaceutical closures. This article explores the manufacturing process, key features, and benefits of choosing a reliable medicine bottle cap mold supplier.

Why Choose Professional Plastic Medicine Bottle Cap Mold Manufacturers?

Pharmaceutical companies demand high-precision molds to meet strict industry standards. Here’s why partnering with an experienced plastic cap mold manufacturer is crucial:

Precision Engineering – Our molds are designed using CAD/CAM technology, ensuring tight tolerances and consistent quality.

Material Durability – We use high-grade steel and alloys to enhance mold longevity and resistance to wear.

Customization – Whether you need child-resistant caps, tamper-evident closures, or flip-top designs, we provide tailored solutions.

Fast Turnaround – With advanced CNC machining and EDM processes, we deliver molds efficiently without compromising quality.

Compliance with Standards – Our molds meet FDA, ISO, and GMP requirements for pharmaceutical safety.

Key Features of Our Plastic Medicine Bottle Cap Molds

Multi-cavity mold designs for high-volume production

Smooth ejection systems to prevent defects

Corrosion-resistant coatings for extended mold life

Automated molding solutions for efficiency

Applications of Medicine Bottle Cap Molds

Our molds are used for:

✔ Prescription drug bottles

✔ OTC medicine containers

✔ Liquid medication caps

✔ Vitamin and supplement packaging

Choosing the Right Plastic Cap Mold Manufacturer

When selecting a medicine bottle cap mold supplier, consider:

✅ Industry experience

✅ Technical capabilities

✅ Quality assurance processes

✅ Customer support and after-sales service

Conclusion

As a trusted plastic medicine bottle cap mold manufacturer, we provide high-performance molds that enhance pharmaceutical packaging efficiency. Whether you need custom injection molds or high-volume production solutions, our expertise ensures top-quality results.

Contact us today to discuss your plastic bottle cap mold requirements and get a quote!