Plastic Cap Molds Precision Engineering for Mass Production & Innovation

Plastic Cap Molds Precision Engineering for Mass Production & Innovation

Core Technologies & Design Innovations

Hot Runner Systems

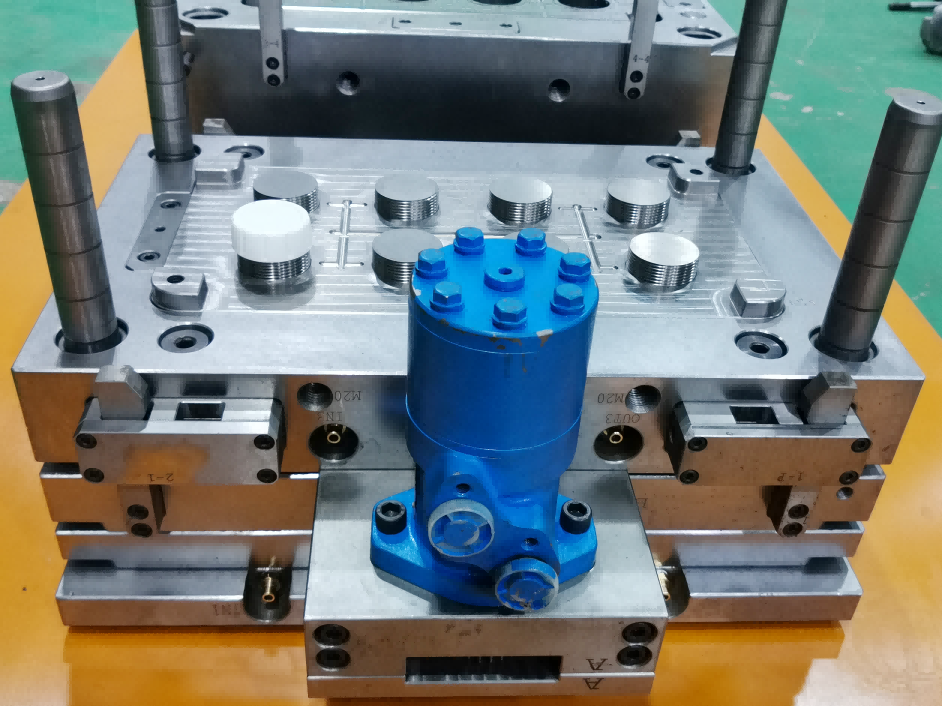

Valve-Gated Molds: Gate positioned at the cap top eliminates surface marks, ideal for premium cosmetic/luxury packaging.

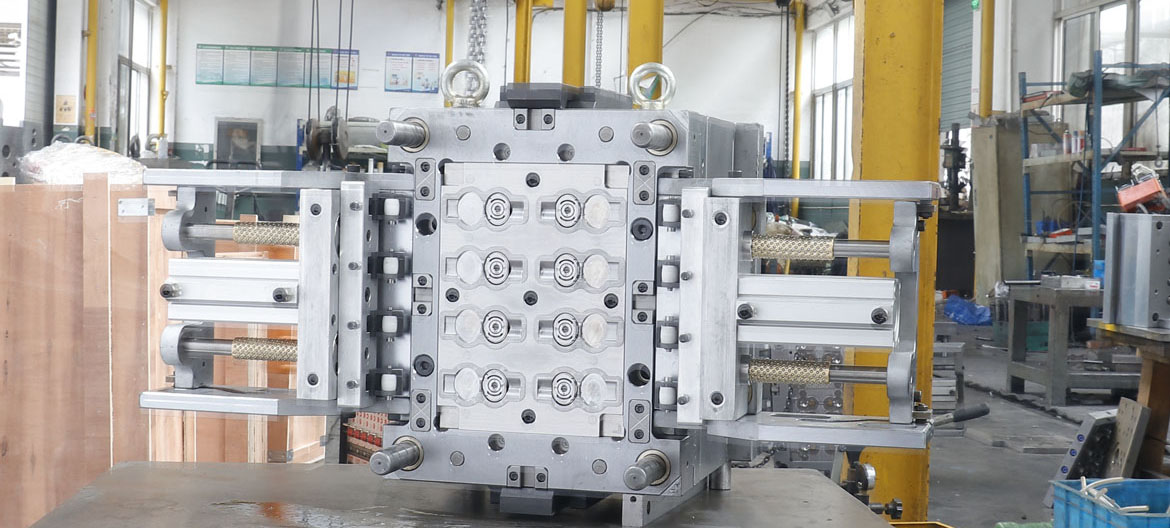

96-Cavity Stack Molds: Zero runner waste, cycle time ≤5 seconds, reducing material waste by 30%.

Multi-Color/Material Molding

Single-step dual-shot molding (e.g., PP flip-top caps + TPE seals) using rotary plates or core-back tech.

Auto-dethreading: Hydraulic motors rotate cores for threaded cap ejection (e.g., medicine bottle caps).

Automation Integration

Servo-driven unscrewing, ejection, and part handling for 24/7 production.

Conformal cooling channels: 3D-printed inserts ensure uniform cooling, minimizing warpage.

Material Selection & Durability

| Component | Material | Hardness/Properties | Application |

|---|---|---|---|

| Cavity/Core | 718H Steel | HRC 52-54 | Beverage screw caps |

| Thread Inserts | H13 Tool Steel | HRC 58-60 | Chemical-resistant caps |

| Cutting Edges | Powdered Steel | HRC 62+ | Flip-top closures |

| Plastic Resins | PP, PE, ABS, PET | Food-grade, UV-stable, impact-resistant |

Industry-Specific Solutions

✅ Food & Beverage

48-128 cavity molds for PET bottle caps (Coca-Cola/Pepsi designs), compliant with FDA/EC1935.

Anti-tamper ring integration & gas-barrier layers.

✅ Pharmaceutical

Child-resistant (CR) closures with torque testing ±0.5 N·m tolerance.

ISO Class 8 cleanroom-compatible molds.

✅ Industrial & Consumer Goods

Large-diameter drum lids (up to 24") with rib reinforcement.

Cosmetic pump dispensers with overmolded silicone seals.

Technical Advancements Driving Efficiency

AI-Optimized Design: Simulation-driven flow analysis reduces trial runs by 50%.

Quick-Change Systems: Interchangeable cores switch cap sizes in <15 minutes.

Sustainable Molding: Bio-resin compatibility (PLA/PHA) and energy-efficient cycles.

Global Supply Chain Capabilities

Rapid Prototyping: 3D-printed mold trials in 72 hours.

High-Volume Production: 10,000+ shots/day with <0.01% defect rate.

Certifications: ISO 9001, ISO 13485 (medical), and IATF 16949 (auto).

Primary Keywords:

Plastic Cap Mold Manufacturer, Injection Cap Molds, Bottle Cap Mold Supplier, Custom Closure Molds, High-Cavitation Cap MoldingLong-Tail Keywords:

Hot Runner Cap Molds, 96-Cavity PET Cap Mold, Child-Resistant Closure Molds, OEM Plastic Cap Molds, Multi-Shot Cap MoldingApplication Keywords:

Beverage Bottle Cap Mold, Cosmetic Lid Molds, Pharmaceutical Screw Cap Molds, Industrial Cover Molding SolutionsCap Mould Manufacturers, Wholesale Bottle Cap Mould Factory