The Precision Engineering Behind Wide-Mouth Jar Mold Manufacturing: A Comprehensive Process Breakdown

The Precision Engineering Behind Wide-Mouth Jar Mold Manufacturing: A Comprehensive Process Breakdown

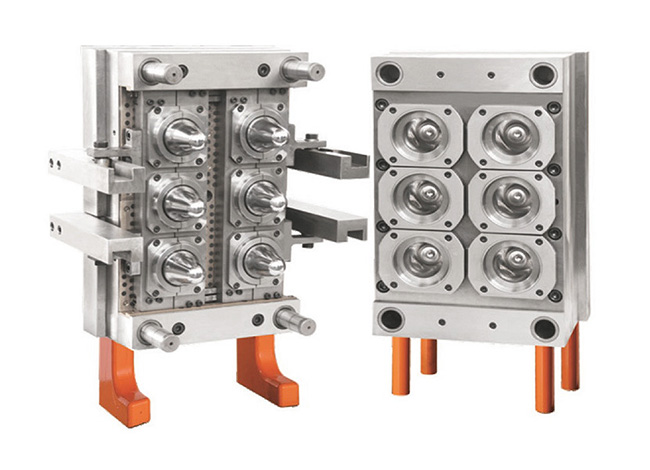

The wide-mouth jar mold manufacturing process represents a pinnacle of precision engineering, where meticulous design meets advanced materials science to produce containers ubiquitous in food packaging, pharmaceuticals, and chemical industries. Unlike standard container molds, wide-mouth designs introduce unique technical challenges—particularly in achieving consistent wall thickness, precise sealing geometries, and efficient production scaling. This comprehensive examination reveals the sophisticated journey from raw steel to functional mold, highlighting innovations that address these industry-specific demands while optimizing for durability, efficiency, and cost-effectiveness.

1. Foundational Design and Engineering Specifications

The mold creation journey begins with digital prototyping, where CAD software translates container specifications into 3D models. For wide-mouth jars, this stage is critical for addressing inherent design challenges:

Sealing Interface Engineering: The thread or lug closure system must maintain sealing integrity under variable pressures. CAD simulations verify thread pitch angles (typically 15-30 degrees) and precise tolerances (within ±0.05mm) to prevent leakage15.

Cavity Layout Optimization: Multi-cavity molds (4 to 96 cavities) require symmetrical runner systems to ensure uniform fill rates. Advanced designs position cavities along the mold's horizontal axis for balanced thermal distribution, reducing warpage in flat flange areas16.

Draft Angle Calibration: Steeper draft angles (2-5°) on jar walls facilitate demolding while maintaining visual straightness—a balance achieved through finite element analysis of material shrinkage behavior5.

Table: Key Design Parameters for Wide-Mouth Jar Molds

| Design Element | Technical Specification | Functional Impact |

|---|---|---|

| Thread Pitch Angle | 15°-30° | Ensures leak-proof closure engagement |

| Cavity Tolerance | ±0.05mm | Prevents flash and parting line defects |

| Draft Angle | 2°-5° vertical walls | Facilitates demolding without distortion |

| Runner Balance | Symmetrical layout | Ensures uniform fill and wall thickness |

2. Precision Material Selection and Treatment

Material integrity dictates mold longevity and product surface quality. Industry-leading manufacturers employ:

Corrosion-Resistant Alloys: P20 steel (HRC 30-36), hardened with vacuum heat treatment, withstands abrasive polymers. Critical components like cores and cavities utilize Swedish 2316 steel (HRC 45), providing exceptional wear resistance beyond 2 million cycles6.

Specialized Surface Enhancements: Thread inserts undergo nitriding treatment (surface hardness >60 HRC) to endure repeated stripping forces without galling. Critical contact surfaces receive PVD coatings like TiAlN, reducing friction during ejection6.

Thermal Management Materials: Beryllium copper inserts in high-heat zones (e.g., gate areas) accelerate cooling, reducing cycle times by 15-20% compared to tool steel alone6.

3. Advanced Machining and Finishing Processes

Transforming raw steel into precision components demands multi-stage machining:

Five-Axis CNC Machining: Creates complex geometries like undercut threads and stacking flanges. Tolerances of ±0.01mm are achieved through iterative machining and in-process CMM verification26.

Electrodischarge Machining (EDM): Shapes intricate texture details on cavity surfaces. Mirror-finish EDM (Ra <0.05µm) eliminates post-polishing for optical-quality jars while preserving dimensional accuracy6.

Conformal Cooling Channel Fabrication: Laser-sintered channels follow cavity contours within 3-5mm of surfaces, enabling 30% faster cooling than drilled channels. This prevents sink marks in thick-bottom sections6.

Table: Precision Machining Standards for Mold Components

| Component | Machining Process | Tolerance Standard | Surface Finish |

|---|---|---|---|

| Core/Cavity | 5-axis CNC + EDM | ±0.01mm | Ra 0.05-0.1µm (optical) |

| Thread Inserts | CNC turning + grinding | ±0.005mm | Ra 0.2µm (nitrided) |

| Ejector System | CNC milling + honing | ±0.02mm | Ra 0.4µm (hard chrome) |

| Hot Runner Nozzles | Micro-drilling + lapping | ±0.03mm | Ra 0.1µm (PVD coated) |

4. Critical Sub-Assembly Fabrication

Specialized components ensure functionality under production stresses:

Hot Runner Systems: Individually controlled nozzles maintain material viscosity within ±1°C. Gate thermal sensors prevent stringing or drool, crucial for clean gate vestige on transparent jars6.

Interchangeable Thread Inserts: Modular designs (ISO 30 mounting) allow quick changeover between thread types (CCL-22, 38mm) or lug closures. Precision grinding ensures inserts seat within 0.02mm runout56.

Cutting Edge Integration: For in-mold trimming, hardened blade assemblies interface with ejectors for clean flash removal during opening cycles7.

5. Automated Assembly and Validation

Final integration transforms components into production-ready systems:

Alignment Engineering: Dual-taper locating rings and interlocks maintain cavity/core alignment within 0.03mm during high-speed cycling. Hydraulic pre-load systems prevent deflection under clamp pressures >300 tons6.

Automated Function Testing: Production simulation verifies:

Ejection sequencing timing (≤0.5s stroke)

Cooling circuit flow balance (±5% between cavities)

Hot runner leakage at operating pressure2

Precision Measurement: 3D scanning confirms wall thickness uniformity (<0.05mm variation). Production samples undergo burst pressure testing (≥35 psi) and leak verification7.

6. Production Integration and Optimization

Seamless transition to manufacturing requires system-level calibration:

Cycle Time Engineering: Conformal cooling enables 15-second cycles for 500ml jars. Automated de-gating eliminates manual handling, while optimized ejection sequences prevent part deformation6.

Process Monitoring: IoT-enabled sensors track cavity pressure, temperature gradients, and ejection forces. Machine learning algorithms predict maintenance needs when parameters deviate >5%2.

Rapid Changeover Systems: Standardized insert mounting (ISO 30) and pre-set components reduce format change time from hours to minutes, supporting small-batch production5.

7. Quality Assurance and Testing Protocols

Rigorous validation ensures production readiness:

Dimensional Metrology: High-precision calipers (±0.015mm/150mm) verify critical sealing dimensions. Custom gauges check thread form compliance to ASTM D3475 standards2.

Durability Testing: Accelerated life testing simulates 500,000 cycles, monitoring for:

Wear-induced flash (>0.02mm unacceptable)

Cooling channel corrosion

Hot runner response degradation6

Production Validation: First articles undergo weight consistency checks (<0.3g variation) and wall thickness mapping via ultrasonic testing. Only molds achieving CpK >1.33 enter production6.

8. Emerging Innovations in Mold Technology

Advancements are reshaping wide-mouth mold capabilities:

Hybrid Additive Manufacturing: Laser-deposited conformal cooling channels now follow complex jar contours, reducing cycle times by 40% while eliminating warpage in PET jars6.

AI-Driven Design: Generative algorithms optimize ribbing patterns for lightweighting (25% material reduction) while maintaining top-load strength >150lbs5.

Self-Lubricating Composites: Nano-impregnated tool steels with embedded solid lubricants reduce ejection forces by 60%, enabling steeper draft angles without sticking6.

Table: Performance Benchmarks for Advanced Wide-Mouth Jar Molds

| Performance Metric | Conventional Mold | Advanced Mold | Improvement |

|---|---|---|---|

| Cycle Time (500ml jar) | 25-30 seconds | 12-15 seconds | 45% reduction |

| Cavity Consistency | ±0.08mm | ±0.03mm | 62.5% improvement |

| Tooling Life | 500,000 cycles | 2,000,000+ cycles | 4x longevity |

| Changeover Time | 2-4 hours | 15-30 minutes | 85% reduction |

Conclusion: The Convergence of Precision and Innovation

The manufacturing of wide-mouth jar molds exemplifies advanced industrial engineering, integrating precision machining, specialized metallurgy, and intelligent automation. From initial design validation through production commissioning, each phase introduces specialized solutions addressing the unique challenges of wide-diameter containers—particularly sealing reliability, dimensional stability, and mass-production efficiency. As additive manufacturing and AI-driven optimization permeate the field, next-generation molds will achieve unprecedented efficiency: zero-changeover designs, self-monitoring components, and production lifetimes exceeding 5 million cycles. These advancements will ultimately transform rigid plastic packaging, enabling lighter, stronger, and infinitely recyclable jars that meet escalating global sustainability demands without compromising performance.