Apex PET Solutions: One-Stop PET Preform Design, Mold Testing & Customization

Apex PET Solutions: One-Stop PET Preform Design, Mold Testing & Customization

Meta Description: Solve your PET packaging problems with Apex's one-stop, turnkey solution. We offer customized PET methods, expert preform design, rigorous mold & sample testing, and accessory customization. Partner with us for end-to-end innovation.

Solve Your PET Problem: Apex's One-Stop, Customized Turnkey Solution

In the fast-paced world of packaging, PET challenges can bring your production to a halt. Whether it's inconsistent quality, inefficient production, or a design that fails to stand out, these problems demand a comprehensive solution, not a temporary fix.

At Apex, we understand these complexities. We don't just supply parts; we provide a seamless, end-to-end partnership. Apex offers a true one-stop solution to solve your PET problem, delivering efficiency, innovation, and reliability from the initial concept to the final production line.

Our Customized PET Method: Engineered for Your Success

We believe every product is unique. That’s why we move beyond standard offerings to deliver a customized PET method tailored to your specific requirements, brand identity, and market goals.

1. Expert Preform Design: The Foundation of Excellence

The preform is the heart of every high-quality PET container. A flawed design leads to a cascade of issues in the blow molding process, including weak spots, material waste, and poor performance. Our engineering team utilizes state-of-the-art simulation software and deep industry expertise to create optimal preform designs. We ensure perfect material distribution, clarity, and strength, laying the groundwork for a superior final product that meets your exact specifications.

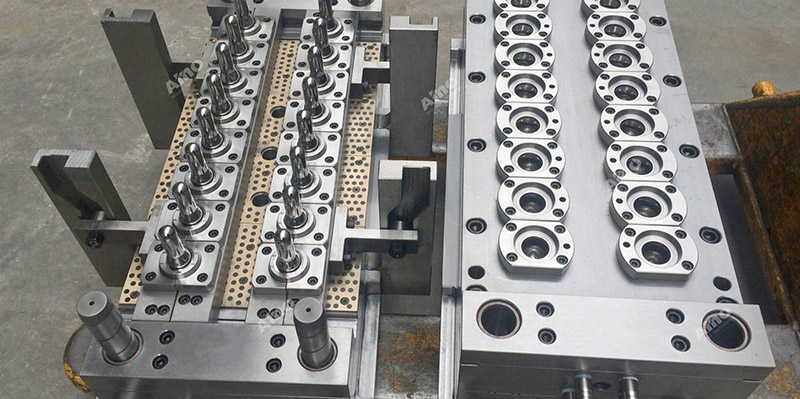

2. Rigorous Mold and Samples Test: Guaranteeing Quality Before Production

Investing in a mold is a significant decision. To de-risk this investment and ensure flawless mass production, our mold and samples test phase is non-negotiable. We manufacture precision molds and produce initial samples for thorough evaluation. This process allows us to validate the design, functionality, and quality of your container, making any necessary adjustments before full-scale production begins. It’s our commitment to delivering certainty and perfection.

3. Complete Accessories Customization: The Finishing Touch

A container is often more than just a bottle. It’s an integrated system. Our accessories customization service covers everything from caps and closures to pumps, sprays, and handles. We ensure these components not only complement your container's design aesthetically but also function flawlessly, enhancing the user experience and ensuring product integrity.

4. End-to-End Turnkey Solution: Your Simplified Path to Market

Why manage multiple vendors when you can have a single, accountable partner? Our turnkey solution integrates every step of the process—from initial design and engineering to mold manufacturing, testing, and production. We handle the complexities, ensuring a smooth, efficient, and cost-effective journey from a raw idea to a market-ready product. This integrated approach saves you time, reduces logistical headaches, and accelerates your time-to-market.

Why Choose Apex as Your PET Solutions Partner?

End-to-End Expertise: From preform design to final assembly, we control the entire process under one roof.

Uncompromising Quality: Our rigorous mold and samples test protocols guarantee that every product meets the highest standards.

Innovation-Driven: We employ advanced technologies and engineering to create innovative customized PET methods that give you a competitive edge.

Collaborative Partnership: We work closely with you, ensuring your vision is realized and your PET problems are solved effectively.

Ready to Solve Your PET Challenge?

Stop dealing with fragmented suppliers and inconsistent results. Partner with Apex for a integrated, reliable, and innovative one-stop solution.

Contact us today to discuss your project and discover how our customized approach can transform your PET packaging.