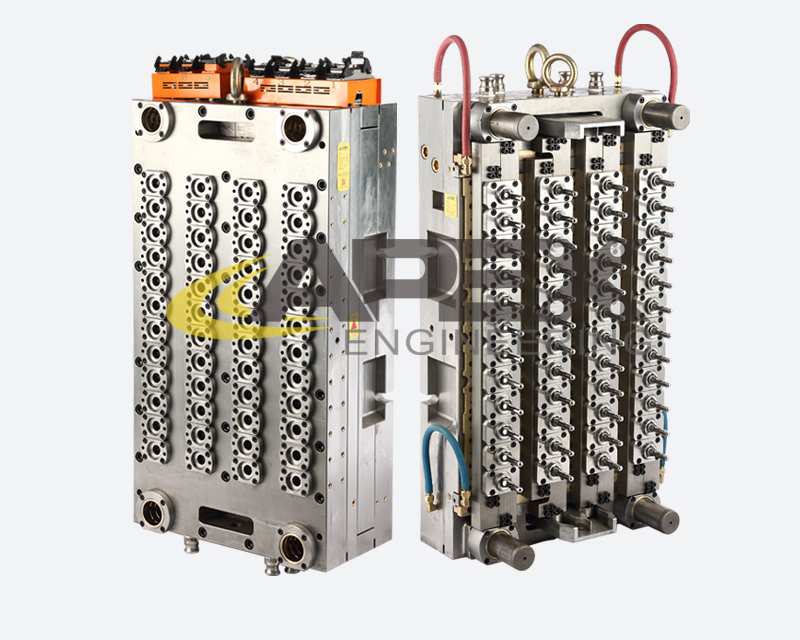

Pet Preform Mould Plastic Mold Manufacturer Pet Preform Injection Mould Multi Cavities

Pet Preform Mould Plastic Mold Manufacturer Pet Preform Injection Mould Multi Cavities

APEX Mould is specialized in injection mould,Electronic products mould,auto & motorcycle accessories mould etc.

As a professional plastic mould maker in China,we have following

advantages:

1. Competitive price

2. High quality, reliability and long mold life

3. Guarantee the delivery time

4. Rich experience for export mold

5. Continuance service and support

APEX MOULD Located in NINGBO,near by HANGZHOU.APEX Mould specializes in injection moulding production and injection mould making. In pursuit to provide our clients with economical solutions, our 9000 square meters facility offers a wide range of machinery, ranging from 60 Tons -1000 Tons precision injection moulding capacities, toatomized robotic arm sorting and packing production lines. As the development of the world economic integration, APEX Mould will spare no efforts in exploring under the principle of " Making your concept into reality". There is no job too small for us. Please enquire so we can help you find a solution.

In-House Design and Manufacturestanding at the forefront of injection moulding and tooling for more than 20 years, APEX Mould prides itself in our In-House Design and Manufacturing. We employ highly skilled and professional operators for our drilling, CNC, EDM, Proprietary Mirror EDM, Mould Polishing machines. APEX Mould passed ISO9001 and IATF16949 quality management system certification. As well as ROHS environmental protection system and SGS certification. SPC is widely used in product development design, mould making, products molding, painting, coating, silkscreen and assembly, to ensure our products in high quality and high finish standard.

APEX Mould strives to produce high quality products and fast delivery times forall our clients by providing a complete service. From start to finish we offer Design,Prototyping, Mould making,production, packaging and shipping. Products covered by the industries of medical devices, beauty and care, household appliances, Netcom products and Auto and so on. APEX Mould's clients from all over the world as: USA, Europe, Brazil, Russia, Australia New Zealand and so on. We always believe technology is the primary productive force for the existence and development of the enterprises.

| Some details of mould | |

| Name | Plastic ice cream box injection mold |

| Mould Material | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20etc |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS etc |

| Cavity No. | Multi Cavity Mold |

| System Of Runner | Hot runner,Cold runner,Pin-point gate,Submarine gate, etc |

| Ejector Type | Ejector pin,Air gate,Ejector plate,Hydro-cylinder,etc |

| Term Of Mould Production | 30days- 55days |

| Guaranteed Of Cycles | 300,000-3,000,000 closing |

| Mould Design Software | Ug,Proe,Solidworks AotoCAD,Moldflow,ect |

| Model Name | Plastic ice cream box injection mold |

| Product Material | PP/PE |

| System of runner | hot runner |

| Shaping Mode | Plastic Injection Mould |

| Product Type | Household Product |

| Injection type | Ejector Pin |

| Mould life | 500000 shots |

| Supply Ability: | 250 Sets per Year Plastic injection mold |

| Packaging Details | Hardly Wooden Case |